Can the Second World War offer a blueprint for solving the coronavirus ventilator challenge?

If British industry giants are to meet Boris Johnson’s demand for 30,000 ventilators, they could learn valuable lessons from the inventive manufacturers of the 1940s, write Jacob Thomas-Llewellyn and Vaughan Michell

Wars often generate “inspirational” tales of underdogs overcoming insurmountable odds. But the heroes in question are normally soldiers, risking their lives behind enemy lines. They don’t usually sit in a boardroom, or design musical instruments and furniture, or run a company which produces kitchen tiles. But that is exactly what some of the unlikely heroes of the Second World War did – before they turned their firms upside down and inside out to create wooden fighter-bombers, harbours, airfields and ocean pipelines for the Allied forces.

It was this 1940s spirit which Boris Johnson was trying to invoke when he called on industry leaders to help the country step up production of vital medical equipment and ventilators in the fight against Covid-19. Just as Winston Churchill called on industry to switch to critical fighter aircraft production, the prime minister was surely hoping he could boost the effort by sheer political will.

Over the crucial summer of 1940, Spitfire production was indeed raised just enough to keep ahead of Germany and so survive the gruelling war of attrition in the skies above southern England that became known as the Battle of Britain. Today Dyson, McLaren and Rolls-Royce – as well as smaller independent innovators – appear to be stepping up to the plate in the battle for ventilator production, while debating the virtues of designing from scratch or copying tried-and-tested methods.

Politicians are keen to hark back to the “Blitz spirit” because during the Second World War Britain was forced to rearm from virtually a standing start. The war offers a possible blueprint for confronting current and future crises, and essential lessons in prompt retooling for mass production and the transformation of a supply chain to respond to immediate global demands.

Speaking after the war, the US director of war production William Knudsen declared: “We won because we smothered the enemy in an avalanche of production, the like of which he had never seen, nor dreamed possible.” Behind this statement was a military-industrial complex that in less than six years had transformed itself.

Firms that had previously manufactured furniture for the mass market converted production lines at an unprecedented pace in order to fabricate high-spec components for Allied combat aircraft. Overnight, the country’s housing industry collapsed with a government-led ban on construction in an effort to conserve key materials and direct skilled labour to essential war work.

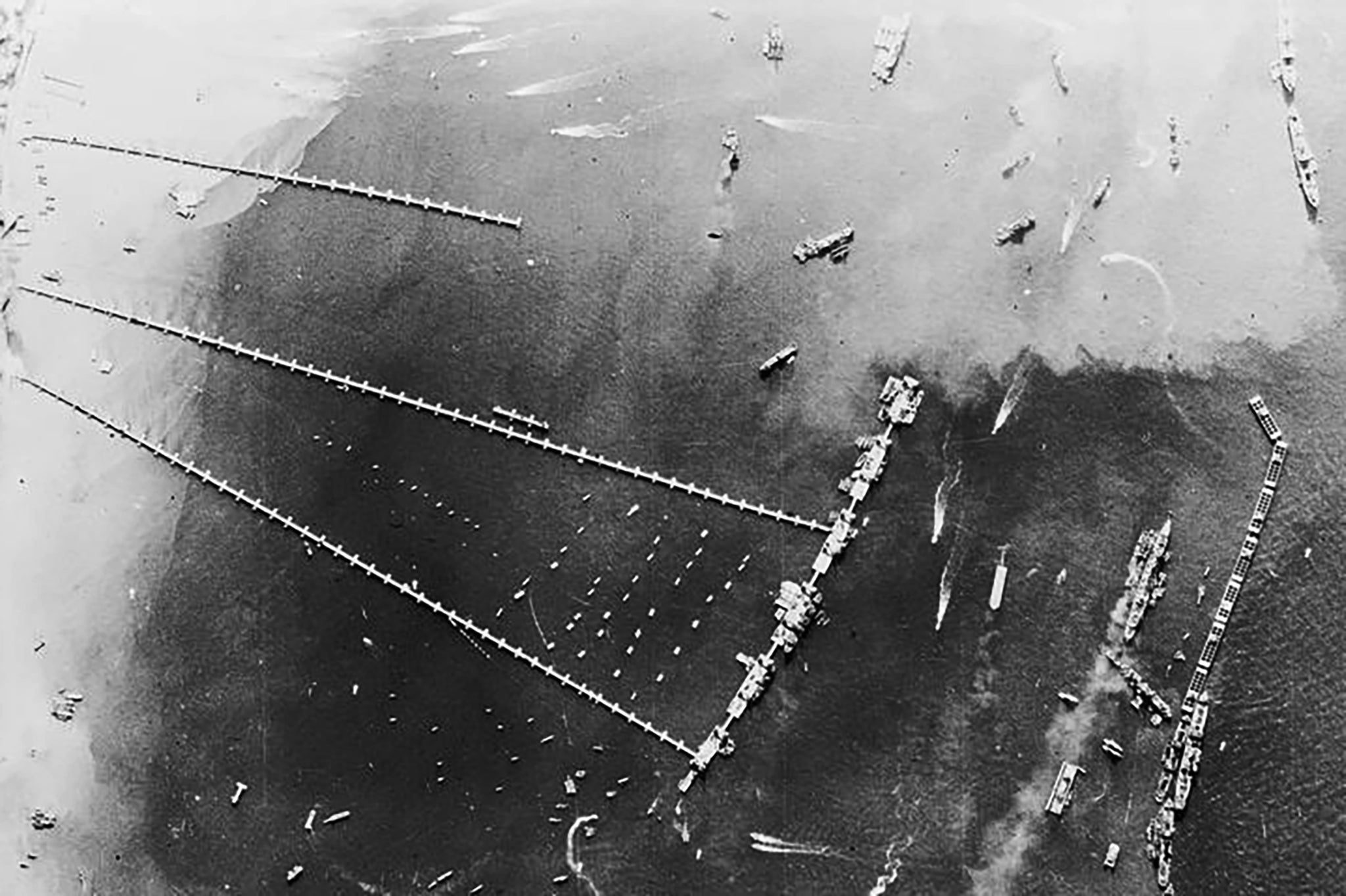

In the midst of this strategic re-prioritisation, the building firm Wates (under the chairmanship of Norman Wates) recognised the importance of reconfiguring production in order to obtain contracts for vital war projects. From 1940, Wates transitioned from civil housing to building airfields, subterranean bomb shelters, petrol barges and 500 floating pontoons (codenamed Beetle) to support bridging equipment to be towed across the English Channel, forming part of the £2bn project to build artificial Mulberry harbours.

The artificially constructed floating docks enabled 2.5 million men, 500,000 vehicles and 4 million tons of supplies to land off the French coast after D-Day. They were designed and built in secrecy by around 50,000 British engineers in the seven months leading up to the landings.

Wates had successfully tailored its manufacturing base to complete projects of which it had no previous experience. Before the war, many of its subcontractors had been responsible for producing garden railings or, in the case of the Marley Company, tiling for the retail market.

We won because we smothered the enemy in an avalanche of production, the like of which he had never seen, nor dreamed possible

This rapid transition was paralleled by a new assurance regime that secretly tested the Mulberry harbour components. Large, detailed scale models were scratch-built to demonstrate that the new technological solutions could survive the exacting environment in which they had to operate. To meet this requirement, the former model train makers were contracted to fabricate large models of every sub-component, which were then rapidly tested in specially designed tanks under the supervision of the National Physical Laboratory. The successful completion of Mulberry harbours is testament to industry’s ability to adapt to a new and unique engineering environment and deliver on time, within strict cost and performance frameworks.

The upscaling of industrial production and reconfiguration to deliver new product lines was borne out by the expansion of the aviation industrial base. A government initiative called the Shadow Factories Programme paid for additional industrial plants and other resources for selected car manufacturers including Rover and Rootes. This allowed them to expand their production floor space and acquire the necessary materials and labour at pre-agreed ramped-up rates.

Cars made way for bombers and fighters and, as the industry expanded, all manner of businesses and experts were drawn into the production effort. The case of the De Havilland Mosquito fighter-bomber represents one of the most unusual, yet successful, examples of collaboration between furniture and musical instrument manufacturers that before 1939 had no experience of fabricating aircraft.

With a fuselage built out of plywood and balsa, the Mosquito was described as “revolutionary” because the methods and material used in the design were a complete departure from those employed in the military aircraft of the late 1930s. With aluminium in short supply, balsa was identified as a bona-fide substitute material.

The ingenious solution resulted in an aircraft that was available in large numbers at relatively modest outlay with the added bonus that it was easy to repair. Canadian press baron and Daily Express owner Lord Beaverbrook – installed as minister for aircraft production by Churchill – declared: “Its methods of construction lent itself to the all-important requirement of dispersal,” to protect plants from bombing. Eventually, more than 400 factories were tasked with manufacturing different components for the project.

These production initiatives could also be exported – and when Britain realised that it did not possess the capacity to produce certain products, it reached out beyond the empire. With the demand for continuous aircraft engine design and a lack of domestic production capacity, Arthur Purvis, the British purchasing agent in the US, approached Knudsen to explore the option of US manufacturers fabricating the Rolls-Royce Merlin engine. The Packard Motor Car Company accepted the challenge and, under contract, Rolls-Royce dispatched the classified engine plans aboard the battleship HMS Nelson.

At a time when Congress was still being persuaded to emerge from its isolationist policy, the knowledge transfer and rapid retooling of US firms to complete British contracts illustrated the ingenuity and flexibility of manufacturers. The fact that before the first engine was built all technical specifications had to be transferred by hand from British imperial to US imperial measures are further proof of the engineering community’s determination.

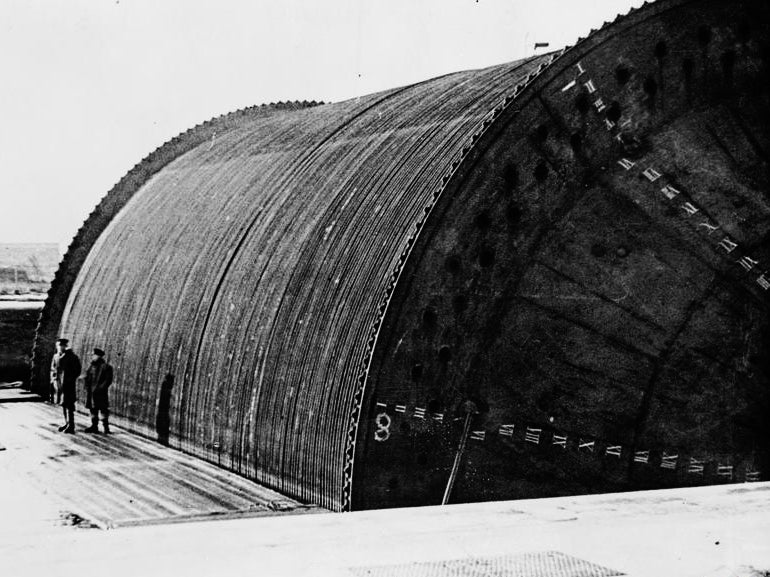

Industry’s expertise in rapid technology transfer was further underwritten by the completion of the unconventional underwater delivery system for fuel transfer across the English Channel to the Allied assault into northwest Europe. Designated Operation Pluto, the idea stemmed from members of the oil industry who envisaged the laying of a sub-sea pipeline from the Isle of Wight to Cherbourg and overland distribution to the fighting echelons.

For the modern observer, lessons from these selected projects should provide confidence in industry’s ability to adapt and adopt new manufacturing techniques to meet the new global threat of Covid-19

By early 1944, every cable, pipeline and rubber manufacturer across Britain had been mobilised to fabricate lengths of specially designed pipeline. By this stage, however, Britain’s production capacity was at saturation point and, as in the case of the Merlin engine, British manufacturers took the designs to the US to supplement their own efforts.

In less than three months, four US firms were manufacturing pipelines for the project. Many companies had no previous experience of fabricating marine pipelines and in the case of one firm, Phelps Dodge, the directors committed to building an entirely new factory including dock facilities and railway yards to ensure the contract was completed.

For the modern observer, lessons from these selected projects should provide confidence in industry’s ability to adapt and adopt new manufacturing techniques to meet the new global threat of Covid-19.

At the start of the year, there were just 4,000 ventilators available to the NHS. This is what galvanised the prime minister to request 20,000 “safe, efficient, oxygen conserving, easy-to-use portable and non-fixed supply” ventilators (totalling about 30,000 when adding overseas orders and increased UK production) from industry leaders. Typically 4.7 per cent of Covid-19 patients become critical and require a ventilator.

Ventilators are complex to build, combining electro-mechanical parts, integrated circuit boards, processors, not to mention tight health standards and manufacturing tolerances. Many parts are also sourced via global supply lines that are now potentially compromised.

There are just two UK ventilator manufacturers, Breas Ltd in Warwickshire and Penlon in Oxfordshire. The US has the largest market share of ventilators produced by firms such as Medtronic, Becton, Dickinson and Teleflex. Europe has the next biggest share led by Philips, followed by China, which is rapidly catching up and which supplies many of the critical parts for other countries.

Despite a standing start – as in both world wars – British industry is responding with heavy equipment manufacturers, with JCB and Rolls-Royce getting in on the act.

The second world war showed that British industry can respond to a crisis with innovation, invention and skill. We need that now and fast

Increasing supply requires knowledge-transfer and tooling with three solution options: expand production of existing designs; simplify existing designs with new or fewer cheaper parts; or re-engineer and reinvent more effective new designs (like the Mosquito) using novel concepts.

The first option enables faster production unless the second can achieve a similar capability with more plentiful or redesigned parts available. The third option takes longer, unless the novel change can use the unique flexible modular architecture involved in microprocessor computing. This enables new programs and software to carry out the rapid innovative improvement.

Re-engineering and fast supply requires multidisciplinary collaboration, so many companies are focusing on production of simpler, positive pressure ventilators to increase capacity. This is what the Dyson has done. Its digital motor capability and the technical knowledge within the company has enabled it to design a new battery-powered “CoVent” ventilator in conjunction with naval defence firm Babcock. It was done in just 10 days and fittingly from their plant in a former Second World War parachute factory in Wiltshire. Dyson has promised 15,000 ventilators.

Rival UK vacuum cleaner company Gtech responded with the second option – reducing the number of parts with an innovative oxygen-powered ventilator design using existing off-the-shelf parts. They repurposed a syringe, instead using it as a piston to inflate a standard hand resuscitation bag. This is mechanically controlled by an improvised pneumatic valve to adjust breaths per minute. The company has made the design publicly available. Company owner Nick Grey said: "We designed the ventilator entirely from parts that can readily be made from stock materials or bought off-the-shelf. This means that Gtech ventilators can be made by almost any engineering and manufacturing company around the world."

4 days

The time taken for Mercedes F1 to design a new ventilator

Other rivals are also putting aside their commercial differences and working with universities and suppliers. The VentilatorChallengeUK consortium includes Airbus, BAE Systems, Ford, Rolls-Royce and Siemens.

Meanwhile, Mercedes F1 has teamed up with University College London to improve upon an existing design for a non-invasive breathing aid using a pressurised, airtight hood delivering air. Oxford University and Kings College’s OxVent project also re-engineered the basic ventilator, reducing multiple components and controls to a single new reprogrammable microprocessor-controlled valve regulating pressure/volume combinations from an air supply inflating a resuscitation bag, to force air into the lungs.

Removing sensors and alarms simplifies manufacturing, enabling fast production by anyone using freely available plans. But while these innovations help, they are a stopgap and lack the detailed air-mix and sophisticated sensors that are needed to fully protect a patient’s lungs from damage in more critical cases.

Developing a suitable ventilator, even a simplified design, is no easy task, as they need to pass clinical trials and meet a range of standards on size, reliability and oxygen mix. For example, the Renault and Red Bull F1 teams’ BlueSky ventilator was rejected from consideration as it did not meet requirements for adjustable settings. So redesigns continue in search of better.

Nonetheless, all these companies are echoing great British engineers such as Robert Whitehead, who created the locomotive torpedo from scratch in 1866 to help improve a clockwork boat bomb for the Austrian navy. These engineers don’t copy, they create new superior solutions.

They are innovators using disruptive technology, such as 3D printing, which enables new ideas to be quickly designed, tested and reproduced by individual printer owners. For example, Italian ventilator air valve supplies were increased by mechanical engineer Alessandro Romaioli, who redesigned a plastic valve in just three hours, to avoid patent infringements, and then 3D-printed and tested it in a day, and then went onto widescale printing production.

The range of plastic, metals and complex geometries that can be printed has enabled medical goggles to be produced in China and the re-engineering of a snorkel into a ventilator mask by a firm in Shropshire.

And there is no shortage of individual engineers and inventors to help, with 3,400 volunteers joining the Helpful Engineering project. The project has 40 different sub-groups, each of which is working on a different strategy for helping to deal with the coronavirus crisis in an open-source and collaborative way.

The Second World War showed that British industry can respond to a crisis with innovation, invention and skill. We need that now and fast. The single specialist manufacturer in the UK highlights the false reliance on service solutions and the lamentable loss of a once thriving and world-leading technology base that supported us through two world wars. Ventilators are critical to the fight to overcome Covid-19 and could save many thousands of lives. They are complicated and specialised pieces of equipment.

Hopefully, the inventiveness and collaboration we are seeing will continue long after this crisis has ended. The government – along with business and academia – must continue to promote, reward and grow this spirit of innovation which helped overcome the odds in previous times of emergency.

The second – perhaps most important lesson – is that the UK needs to design, fabricate and control many more of its own products, particularly strategic goods to reduce supply chain trauma. Finally, the government must invest in Britain over the long term as the re-engineered intelligent workshop of the world to ensure scientists, engineers and mathematicians are valued and supported to work together and so reduce the folly of short-term profits for long-term pain.

Jacob Thomas-Llewellyn is a PhD candidate and military researcher at the University of Reading. Vaughan Michell is the programme director of MSc business technology consulting at the University of Reading. This article first appeared on The Conversation

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies

Comments