Liquid nitrogen cooled 3D ice cream printer invented by MIT students

The team hacked together an ice cream maker and 3D printer, placing their invention in a freezer and keeping it cool using liquid nitrogen

3D printing technology has already been used to liven up sugar cubes and chocolate, but now a trio of students from MIT have created the world’s first 3D ice cream printer.

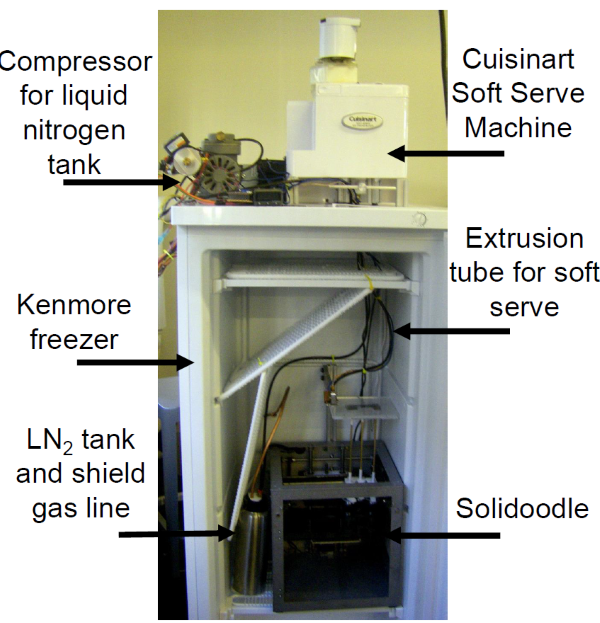

By hacking together a soft serve ice cream maker, a freezer and a 3D printer, Kyle Hounsell, Kristine Bunker, and David Donghyun Kim were able to create a machine that extrudes soft ice cream into any given shape then quickly freezes it with a blast of liquid nitrogen.

"First, we needed to print into a cooled environment so that the ice cream would hold its shape once printed,” the students explained to 3D printing site 3Dprint.com. "We bought a small upright freezer which was large enough to both put the Solidoodle inside and allow for the full build volume we were aiming for."

The setup also includes a temperature control system which keeps the extrusion nozzle (where the ice cream is pumped out) at 18°F (-7C) as soft serve ice cream begins to melt completely at just two degrees warmer than this.

Although the print area is only roughly the size of someone’s hand, the students say this was necessary to keep the print time low.

"We felt that waiting more than 10-15 minutes for an ice cream to be printed would cause the consumer to lose interest,” they explained. "Additionally, this was a short enough time for the ice cream to keep its shape in the freezer would excessive liquid nitrogen being poured onto it.”

The students say that they hope their invention could get more children interested in the technology and that similar demonstration devices could be marketable in American ice cream parlours where customers could order a custom ice cream and pick it up 15 minutes later.

Click here to find out more technical details about the project

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies

Comments

Bookmark popover

Removed from bookmarks