How Apple is making the chips that power its computers – and why its Macs are turning green

New silicon is making Macs faster – but could also help cut down their energy use

In Munich, sandwiched between breweries and beer gardens, stands something Apple knows only as “Karl”. The building – named after Karlstrasse, the road on which it stands – is in part a grand testament to an even grander plan by the company.

That plan is known broadly as Apple silicon, and it is happening not only inside Karl but at a range of more or less secretive buildings around the world. Put a little less broadly, it was the major departure that Apple made around three years ago, when it announced that it would start designing its own chips to power its Mac computers.

Apple silicon was the latest part of decades of work by the company to design and make as much of its products as possible. It appears to have paid off.

Apple says that the integration it has allowed has made its computers vastly more capable and powerful, an assessment that has repeatedly been echoed by the reviewers who use them. By bringing its hardware, software and product design work together, it also says that it has been able to create experiences and products that would never have been possible before.

But it also says that it has paid off in other ways, too. The new chips are not only more powerful but also less power-hungry, doing their work far more efficiently than before.

That helps in obvious ways, such as vastly increasing the time between charges of its devices even with the same-sized battery. But there are more subtle and arguably more important ways that helps – such as cutting down the amount of energy used by its devices, and in so doing helping reduce the carbon footprint both of Apple and the people who used its products.

In 2020, Apple made an announcement that was no less shocking for the fact that many had predicted it would arrive. It was going to design its own chips, it said, and move away from the Intel processors that had powered its computers for 15 years.

The announcement was significant but at that point seemed inevitable: the Apple-designed chips that had been used in the iPhones for years at that point had started to rival and in some cases outpace the Intel ones in its computers. The first chip was called the M1, and took the same efficiency and power that marked out the iPhone’s silicon and made it large enough to power a whole computer.

In the time since, Apple has released the M2 chip, which sped up that original version even more. And Apple also made Pro, Max and Ultra versions of those processors, capable of powering its professional devices.

Within Apple, that process was even more inevitable. The company watched as the chips inside its iPhone and iPads became quicker, and then came to realise that those same technologies would work in bigger and more power-hungry devices.

“As we got into several generations of iPhone, and iPad, and we saw the incredible capabilities and performance they were delivering – on top of that the innovation in other areas around other technologies that went into the [chip] – we had tremendous belief on where that could take the Mac,” says Doug Brooks from Apple product marketing, speaking in Munich.

“And so when we ventured into the Apple Silicon transition in 2020, that was really our time to, you know, jump in and take advantage of that.”

Apple has long talked about the fact that it makes both the hardware and software for its products, and that the combination of the two means that it is able to control the user’s experience in a way that other companies cannot. Under Tim Cook, that has only become more central to Apple’s business, as it has looked to move all of its core technologies under its own control.

The release of Apple Silicon seemed to be the ultimate distillation of that claim: at last, Apple was controlling the design of its Macs to the very smallest extent. And the performance showed it was true, with the first Macs receiving widespread plaudits that have not stopped with the release of those new computers.

That performance meant that though the decision to move was a significant one, it was also one that almost made itself, says Brooks.

“I look at it as really seeing that fundamental trajectory that Apple silicon was on, you know the rapid improvements that the CPU cores and GPU cores had seen over iPhone. In 2020 we said the CPU performance grew 100 times over 10 generations of iPhone, and the GPU performance in the most powerful iPad was 1,000 times greater than the first iPad,” he says.

“The trajectory was just amazing, right, and we had worked generation over generation to get more capabilities that really gave us a tremendous trajectory to believe Apple silicon could be transformative, and we’re extremely proud how well that has done.”

Brooks was speaking from the Munich lab, which is one of a range of similar buildings across the world. There are those in Apple’s home of California, as you’d expect, but there are others such as this one in Germany and in Israel.

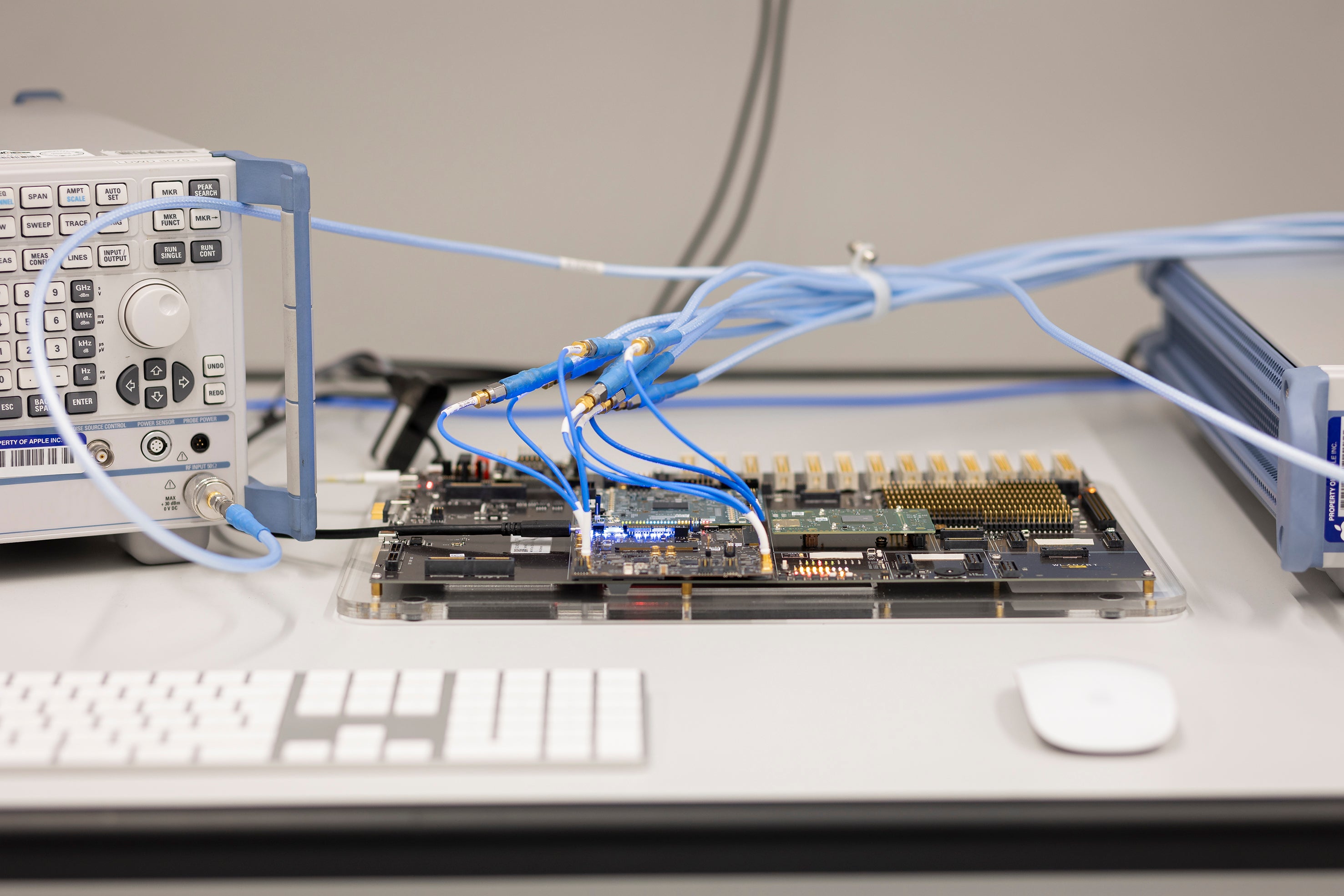

Engineers inside those offices work together and apart, on a range of technologies, which are then integrated into the whole. In Munich, for example, the work has focused on technologies including the power management unit or PMU, a microchip that ensures the other parts of the system are getting the energy they need, and the cellular connections that allow iPhones to connect to 5G networks.

(Apple doesn’t make its own cellular chips, yet, but has been clear that it is looking into doing so, and rumours have suggested that they could be ready in 2025. For now, the cellular room filled with is being used to test whether cellular chips interfere with the Apple-made processors – but it isn’t difficult to speculate on what might be happening when its grand doors are closed.)

The Munich lab is set out a little like a big microchip itself: Apple runs the whole building, and staff are sweeping around to various, specialised parts of Karl, with each room serving its own purpose. Together they add up to work like a big chip, making very little chips.

That work going on at Munich and elsewhere has in part meant trimming down the chip, allowing it to be both smaller and more refined. Before Apple Silicon, the chip in the Mac was a large and sprawling thing, which was required to talk to various other parts to get its job done, but by designing the entire thing Apple has been able to make it far more efficient.

One of the innovations that helps the power of Apple Silicon is the unified memory architecture, which allows various parts of the system such as the CPU and GPU to tap into a combined pool of memory. That means that data is shuttled around a lot less within the computer, which in turn speeds it up and cools it down; though the extra distance is tiny, it happens an awful lot, and requires a host of other technologies to ensure that it happens.

If Apple’s office works like a big microchip, then the work that architecture and other parts of the design are doing is the equivalent of cutting the walk to the printer in half. Imagine how much time and energy that would save if you had to walk to the printer thousands of times each second.

The design also means that the inside of the computer is more beautiful than you might imagine, and those chips look like little iPods themselves. Inside Apple’s labs are deconstructed versions of computers using both Apple’s chips and those from Intel, and it turns out the precisely engineered nature of the former is as clear when you tear them apart as when you turn them on.

That precision has helped Apple achieve goals that would not seem obviously related to the specialised work that is going on inside those labs in Munich and elsewhere. The computers are faster, cooler and more long-lasting, yes – but they’re also greener.

The carbon footprints of devices, as Apple measures it, doesn’t end when they leave the shelves. Apple continues to count the full life cycle of the product in its carbon footprint, which means that people’s usage of them is factored into the target.

It is also committed to getting rid of that carbon footprint entirely. It has committed to do so by 2030, and so the race is on to remove dirty energy use through the whole process, from creation to disposal.

In 2021, the latest figures that Apple has released, customers’ use of products counted for 22 per cent of the company’s carbon footprint. It can do whatever it wants to reduce the 78 per cent that remains, but the rest will always stick around as long as people are using its devices.

It has done some more large-scale work to help reduce that: a recent feature called Clean Energy Charging allows people in the US to switch their iPhone so that it charges up at times when the grid is using greener sources.

But it will also require less obvious work, like that happening in Munich. If the computers and their chips use less energy in the first place, there will be less of a concern about where that energy is coming from.

Apple has clearly committed to the philosophical principle underpinning the development of its new chips: that it is better to start with a chip designed for mobile, and make it bigger and more powerful, than it is to work with chips for which size was never a factor.

Building them that way means that users of even big systems such as Apple’s top-end Mac Studio and MacBook Pro get the advantages of a mobile chip, in the form of extra efficiency, less heat and more. But are there disadvantages to doing so?

“I don’t think so,” says Brooks. “I think the Mac product line that we're building today is the best we've ever had, right? And inherently, so much of that comes from the incredible performance and power efficiency that the Apple Silicon provides.

“And that builds on the legacy that we started with the iPhone. So I think it's been just a tremendous advantage for us.”

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies

Comments