Coronavirus: Health and safety breaches at testing lab

Exclusive: Health and safety watchdog finds ‘material breaches’ in five areas at coronavrius lab handling 40,000 tests a day

Your support helps us to tell the story

From reproductive rights to climate change to Big Tech, The Independent is on the ground when the story is developing. Whether it's investigating the financials of Elon Musk's pro-Trump PAC or producing our latest documentary, 'The A Word', which shines a light on the American women fighting for reproductive rights, we know how important it is to parse out the facts from the messaging.

At such a critical moment in US history, we need reporters on the ground. Your donation allows us to keep sending journalists to speak to both sides of the story.

The Independent is trusted by Americans across the entire political spectrum. And unlike many other quality news outlets, we choose not to lock Americans out of our reporting and analysis with paywalls. We believe quality journalism should be available to everyone, paid for by those who can afford it.

Your support makes all the difference.One of the UK’s coronavirus mega-labs has breached health and safety rules – with scientists warning of “chaotic and dangerous” practices at the testing facility.

Whistleblowers who worked at the Lighthouse Laboratory in Milton Keynes have alleged that workers receive insufficient training before each being asked to handle tens of thousands of coronavirus test samples every day.

A joint investigation by The Independent and the BBC also uncovered concerns about a lack of social distancing, poor protective clothing, and unsafe handling of samples by staff under pressure to process as many tests as possible as Britain tried to ramp up its coronavirus testing programme.

The UK network of Lighthouse Laboratories, run by private organisations on a not-for-profit basis, was set up in a matter of weeks in April to rapidly expand daily testing capacity. Initially there were three labs, in Milton Keynes, Manchester and Glasgow. There are now seven mega-labs around the country aiming to process a combined total of at least 500,000 tests a day by the end of October.

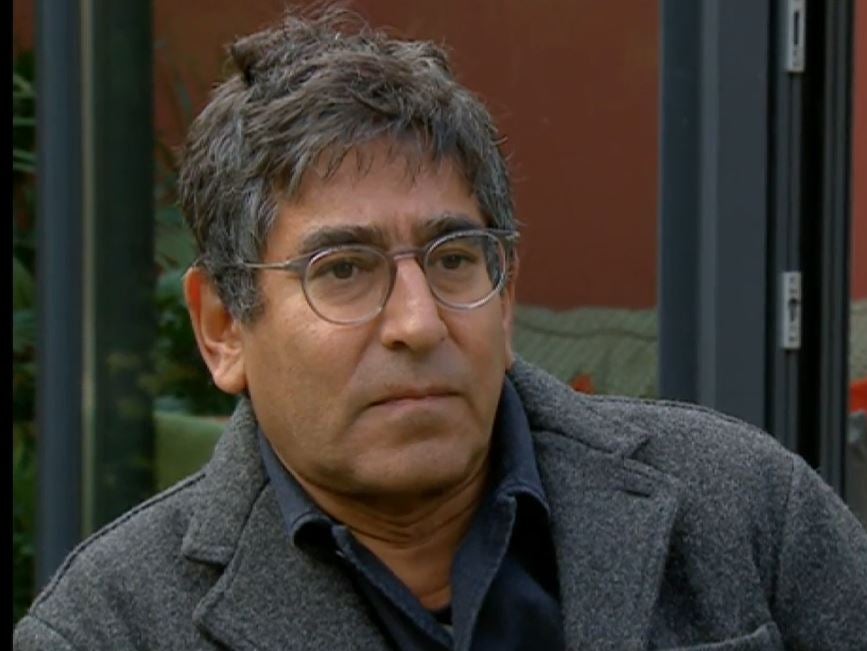

But Dr Julian Harris, an experienced virologist who worked at the Milton Keynes site during July and August, told The Independent he had been “appalled” by the lack of training and adherence to safety standards.

He said he believed many of those recruited to work in the labs had been unaware of the dangers.

“They were putting themselves at risk of infection, but they didn’t know it because they hadn’t been properly trained," he said.

Following a complaint by Dr Harris, the Health and Safety Executive visited the Milton Keynes lab twice and confirmed it had identified five separate “material breaches” of health and safety legislation.

The watchdog said these related to social distancing, cleaning regimes and safety training. The lab has been told to make improvements to increase cleaning in high-touch areas and to ensure “competent” staff deliver health and safety training.

The UK Biocentre, which runs the Milton Keynes lab, said it had strict safety measures in place and was making improvements.

Some of Dr Harris’ concerns were accepted by managers at the lab, which handles around 35,000 test samples a day, during a meeting in August after he raised safety concerns internally. One senior manager told him that, due to university staff leaving and being replaced by less-experienced workers, the training in place did not appear to him to be “robust enough”, adding that he felt there was a “fundamental issue” with protocols not being followed properly.

In September, Boris Johnson wrote to universities urging them to release 400 staff to help at the Lighthouse Labs amid concerns workforce shortages would hit the ability to process tests. Dr Harris, who started working in laboratories dealing with highly infectious diseases in the 1980s, said he quickly became concerned at what he saw when he started work in the lab on 6 July.

He described the initial training as “rushed” with no reference to specific issues linked to working in a biosafety level-two lab such as Milton Keynes. He also said there had been a lack of signage, spill kits in case samples were dropped on the floor and there was a lack of knowledge by staff about what to do when this happened.

“At the induction I felt I was surrounded by people who didn’t know anything about biosafety or handling infectious pathogens,” he said. “These people don’t realise that they’re in harm’s way. And it’s quite easy and quite straightforward to train them. They’re not and this is what’s deplorable.”

He added: “I saw complete overloading of the biosafety cabinets and when you do that the air flow has nowhere to go.

“They actually had racks full of tubes plonked right on the front grate and I saw that numerous times. So people were getting no protection whatsoever. I am convinced they were putting themselves at risk of infection but they didn’t know it because they hadn’t been properly trained.”

The UK Biocentre said two staff were used to operate the safety cabinets with the second worker witnessing and supporting the scientist using the cabinet. It said staff had three days of mandatory training first.

Another former worker at the lab told The Independent: “I immediately began to question some of the most basic practices that were being employed in the labs. It was like we were set up to work on a war-footing with massive enthusiasm for the task but many of the things we could implement from existing industry and lab practice to make things more efficient and safer for the work team were not used.”

The insider, who asked not to be named said: “On my shifts I was sitting in front of a biosafety cabinet for hours and each hour was opening 320 sample bags, making repeated actions requiring significant force. There were no rotations between tasks, not enough breaks for this type of work and basic lab practices to avoid injury from this repetitive work did not appear to be a consideration.

“We had disposable visitors lab coats with gloves taped to the sleeves with brown parcel tape to reach into cabinets, no plastic sleeves like at other facilities.”

In a statement the lab said staff did now have access to both cloth and disposable lab coats and tape was used as an extra safety measure because staff are told to wear two pairs of gloves.

Reacting the concerns of the whistleblowers, Professor Deenan Pillay, a professor of virology at University College London, said he believed part of the problem had been an “obsession with outsourcing” by government.

He said: “Laboratories that undertake diagnostic work for dangerous pathogens, which Covid-19 is, are dangerous places to be.

“The Lighthouse Labs started off with PhD students and the like coming from universities who had never done diagnostic testing before. It is not surprising there are health and safety issues if training is not appropriate. It concerns me that we are depending as a nation on laboratories which are struggling to staff themselves.

“I think the way the government has approached this has been to spend inordinate amounts of money – billions and billions of pounds on outsourcing. There will be a focus on just how the public sector has been undermined rather than utilised to the best of its strengths in dealing with a pandemic.”

The UK Biocentre, which runs the Milton Keynes lab, said it was taking action over the issues raised by the Health and Safety Executive (HSE) but added the regulator had not issued it with a formal notice.

The Independent understands the HSE has written to the lab setting out the actions it expects to be taken. A HSE spokesperson said: “Following an inspection, HSE identified material breaches of health and safety legislation and has informed UK Biocentre Ltd of these in writing.”

A UK Biocentre spokesperson said: “We take the health and safety of all our staff very seriously and actively encourage the scientists and other colleagues to suggest improvements and raise any concerns. We’re grateful for the support and advice from the HSE as we continue to scale up our operations to meet the country’s testing needs. HSE has made some observations that we are addressing as we continue to expand our testing capacity to tackle the coronavirus.

“For the avoidance of doubt, HSE has not issued an improvement notice, but we actively welcome their expertise to ensure the safety of our lab teams who are working tirelessly as part of a diagnostics network that is operating at a scale that this country has never seen before. We are making sure that all those working at UK Biocentre have the appropriate skills and receive any necessary training. We assess all employees on an assessment day before providing a full-day induction – which includes Health and Safety procedures. This is then followed by an additional, lab-specific induction.”

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies

Comments