Double helix of bricks: How a 600-year-old dome built during the Italian renaissance could inform construction techniques today

Despite numerous theories, it was unknown exactly how the domes were built without the use of temporary supporting structures. Now, Harry Cockburn reports, detailed computer analysis allows researchers to look at the forces at work in each individual brick

The astonishing duomo, which has floated miraculously over the Cathedral of Santa Maria del Fiore in Florence for almost 600 years, is credited as a centrepiece of the Italian renaissance.

The self-supporting octagonal masonry dome, designed by Filippo Brunelleschi and completed in 1434, became an exemplary architectural feat of the era. At 45.5 metres across, it is still the largest masonry dome in the world.

What’s more, the design required little scaffolding and no central “shoring” to hold up the dome while it was under construction.

Similar designs were used in the later construction of the basilica of St Peter’s Cathedral in Rome (1535) and the Santa Maria in Ciel d’Oro dome in Montefiascone (1548), both designed by Antonio Sangallo.

Now, architects are returning to these renaissance engineering techniques to find out how they could inform modern-day construction projects.

A collaborative study by researchers at Princeton University in the US and the University of Bergamo in Italy has shone a light on one of the key engineering techniques behind the construction of these self-supporting masonry domes.

The study claims to be the “first ever” to quantitatively prove the physics at work in Italian renaissance domes and explain the forces which allow such structures to have been built without the formwork typically required, even in modern construction.

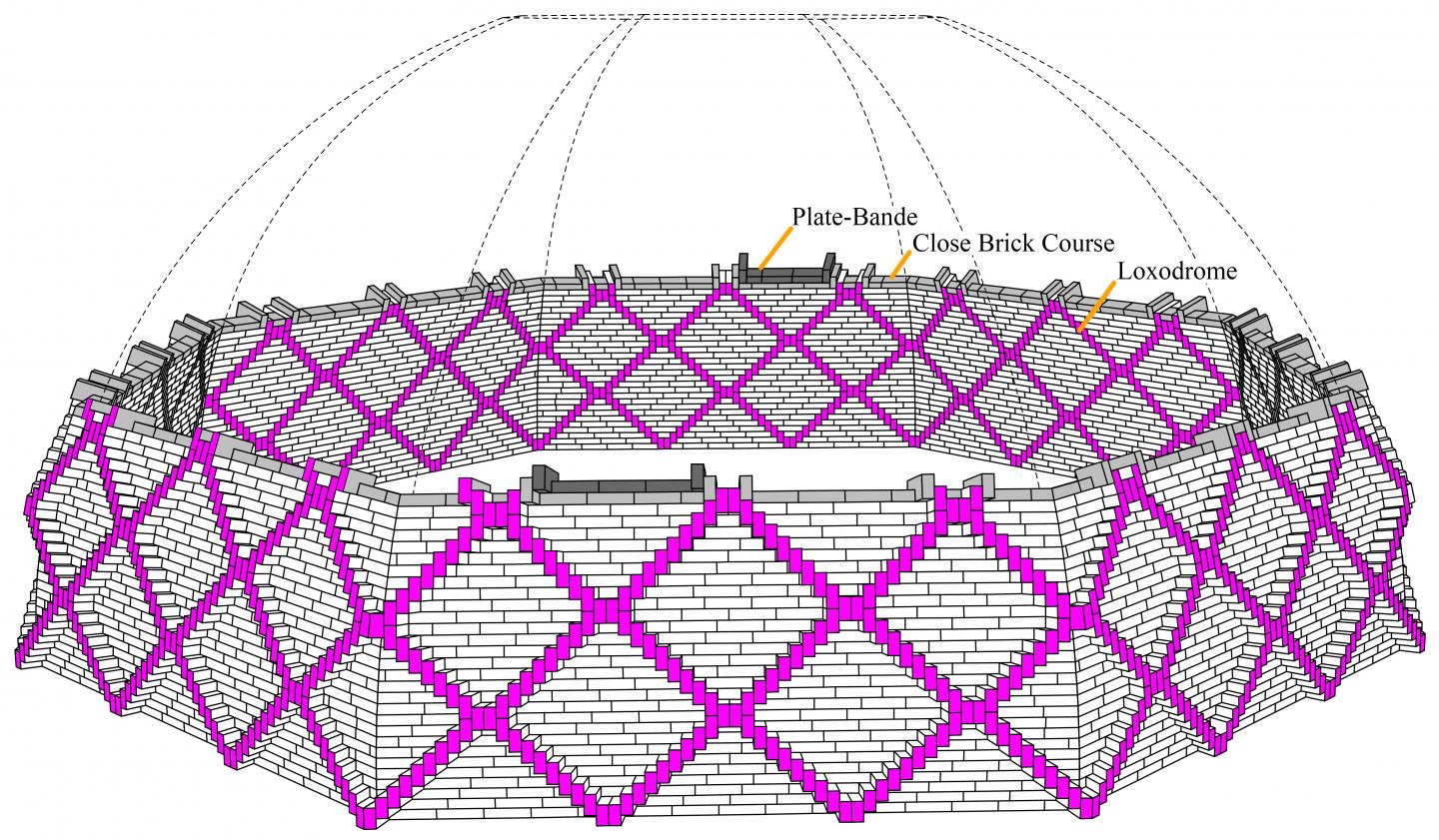

The study, published in Engineering Structures, reveals a hidden “double helix” of masonry on an “inner dome” is key to distributing forces evenly through the structure to allow it to be self-supporting. This then allows the construction of the outer dome layer.

The use of such masonry helixes is known as the “double loxodrome technique”, and it consists of rows of vertical bricks laid in a herringbone pattern which spiral around the dome.

Horizontal bricks are then used to fill the gaps, with each new layer creating a structural element known as a plate-bande, or flat arch, which wedges the horizontal bricks between the vertical ends to distribute load across the structure.

The study states: “This layout can be applied to a wide range of dome geometries such as hemispherical or octagonal forms.”

Sigrid Adriaenssens, professor of civil and environmental engineering at Princeton, collaborated on the analysis with graduate student Vittorio Paris and Attilio Pizzigoni, professor of engineering and applied sciences, both of the University of Bergamo.

Previously, there were only hypotheses in the field about how forces flowed through such domes, and it was unknown how they were built without the use of temporary structures to hold them up during construction.

Professor Adriaenssens said the study aimed to answer two key questions: “How can mankind construct such a large and beautiful structure without any formwork – mechanically, what’s the innovation?” she asked.

And secondly, “What can we learn? Is there some forgotten technology that we can use today?”

The team used detailed computer analysis which accounts for the forces at work down to the individual brick, precisely explaining how equilibrium is leveraged.

The technique, called discrete element modelling (DEM), analysed the structure at several layers and stages of construction.

The team said not only do their tests help us understand the mechanics of the structures, but also make it possible to recreate the techniques for modern construction.

The researchers anticipate their study could have practical applications for developing construction techniques in which aerial drones and robots are used.

They say use of unmanned machines for construction could increase worker safety, as well as speed up construction and reduce costs.

They claimed this could also reduce the impact of the construction industry on the environment.

“The construction industry is one of the most wasteful ones, so that means if we don’t change anything, there will be a lot more construction waste,” said Professor Adriaenssens, who is interested in using drone techniques for building very large span roofs that are self-supporting and require no shoring or formwork.

“Overall, this project speaks to an ancient narrative that tells of stones finding their equilibrium in the wonder of reason,” said Professor Pizzigoni.

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies

Comments