Scientists use bread-eating fungi to create ‘sustainable alternative’ to leather

PhD student Akram Zamani says her ‘fungal leather’ takes less time to produce than other alternatives on the market and is 100 per cent bio-based

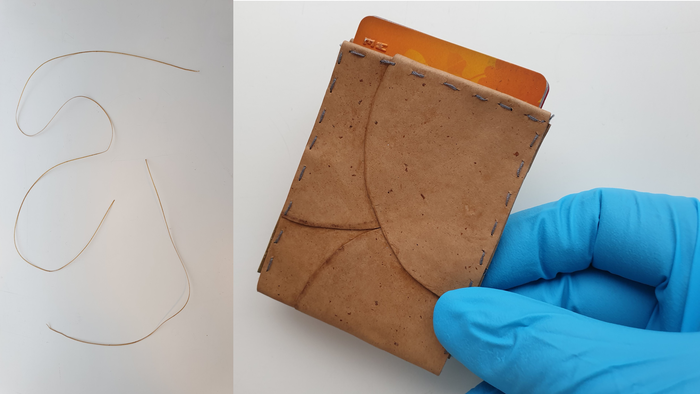

Scientists say they want to harness a “bread-eating fungus” to make faux leather fashion accessories such as handbags and wallets.

Researchers presenting at a spring meeting of the American Chemical Society earlier this week said they used organisms to convert food waste into faux leather, as well as paper products and cotton substitutes.

They said that the “fungal leather” takes less time to produce than existing substitutes on the market and unlike some, is 100 per cent bio-based.

PhD student Akram Zamani said she set out to find replacements for cotton, which is in short supply and leather, which is made from the hide of an animal.

“We hope they can replace cotton or synthetic fibres and animal leather, which can have negative environmental and ethical aspects,” says Ms Zamani, the project’s principal investigator.

“In developing our process, we have been careful not to use toxic chemicals or anything that could harm the environment,” Ms Zamani added.

Ms Zamani and a team of researchers from the University of Borås in Sweden collected unsold bread from supermarkets, dried it out and ground it into breadcrumbs.

They mixed this with water in a pilot-scale reactor and added spores of Rhizopus delemar, which can typically be found on decaying food.

As the fungus fed on the bread, it produced microscopic natural fibers made of chitin and chitosan that accumulated in its cell walls.

After two days, the scientists collected the cells and removed lipids, proteins and other byproducts that could be used in food or feed.

The remaining jelly-like residue consisting of the fibrous cell walls was then spun into yarn, which could be used in sutures or wound-healing textiles and perhaps in clothing.

The suspension of fungal cells was laid out flat and dried to make paper - or leather-like materials.

The first prototypes of fungal leather the team produced were thin and not flexible enough, Ms Zamani said.

“Now the group is working on thicker versions consisting of multiple layers to more closely mimic real animal leather.

These composites include layers treated with tree-derived tannins — which give softness to the structure — combined with alkali-treated layers that give it strength.

Flexibility, strength and glossiness were also improved by treatment with glycerol and a biobased binder.

“Our recent tests show the fungal leather has mechanical properties quite comparable to real leather,” Ms Zamani added.

For instance, the relation between density and Young’s modulus, which measures stiffness, is similar for the two materials.

While some other fungal leathers have already reached the market, little information about their production has been published, and their properties don’t yet match real leather, according to Ms Zamani.

She claims some commercial products are made from harvested mushrooms or from fungus grown in a thin layer on top of food waste or sawdust using solid state fermentation.

Such methods require several days or weeks to produce enough fungal material, she says, whereas her fungus is submerged in water and takes only a couple of days to make the same amount of material.

A few other researchers are also experimenting with submerged cultivation but at a much smaller scale than her group’s efforts.

In addition, some of the fungal leathers on the market contain environmentally harmful coatings or reinforcing layers made of synthetic polymers derived from petroleum, such as polyester, Ms Zamani said.

That contrasts with the University of Borås team’s products, which consist solely of natural materials and will therefore be biodegradable, Ms Zamani expects.

Her team is working to further refine their fungal products.

They also recently began testing other types of food waste, including fruits and vegetables.

“Instead of being thrown away, it could be used for growing fungi,” Ms Zamani says. “So we are not limiting ourselves to bread, because hopefully there will be a day when there isn’t any bread waste.”

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies

Comments