Swedish company makes world’s first delivery of ‘Green Steel’ made without using coal

‘Test delivery is an important step toward a fully fossil-free iron and steel production value chain’

Your support helps us to tell the story

From reproductive rights to climate change to Big Tech, The Independent is on the ground when the story is developing. Whether it's investigating the financials of Elon Musk's pro-Trump PAC or producing our latest documentary, 'The A Word', which shines a light on the American women fighting for reproductive rights, we know how important it is to parse out the facts from the messaging.

At such a critical moment in US history, we need reporters on the ground. Your donation allows us to keep sending journalists to speak to both sides of the story.

The Independent is trusted by Americans across the entire political spectrum. And unlike many other quality news outlets, we choose not to lock Americans out of our reporting and analysis with paywalls. We believe quality journalism should be available to everyone, paid for by those who can afford it.

Your support makes all the difference.Swedish joint venture Hybrit has made the world’s first customer delivery of “green steel,” produced without using coal, to truck-maker Volvo Group, the group said on Wednesday.

Studies have shown that conventional processes emit nearly two tonnes of carbon dioxide for every tonne of steel produced, with global manufacture of the alloy accounting for about 7-8 per cent of greenhouse gas emissions.

HYBRIT, which stands for Hydrogen Breakthrough Ironmaking Technology, was created in 2016 by the steel maker SSAB, the mining company LKAB, and the energy firm Vattenfall with the aim of developing a technology for fossil-free iron-and steelmaking.

“The test delivery is an important step toward a fully fossil-free iron and steel production value chain and a milestone for the HYBRIT partnership between SSAB, LKAB and Vattenfall,” the Hybrit partnership noted in a statement.

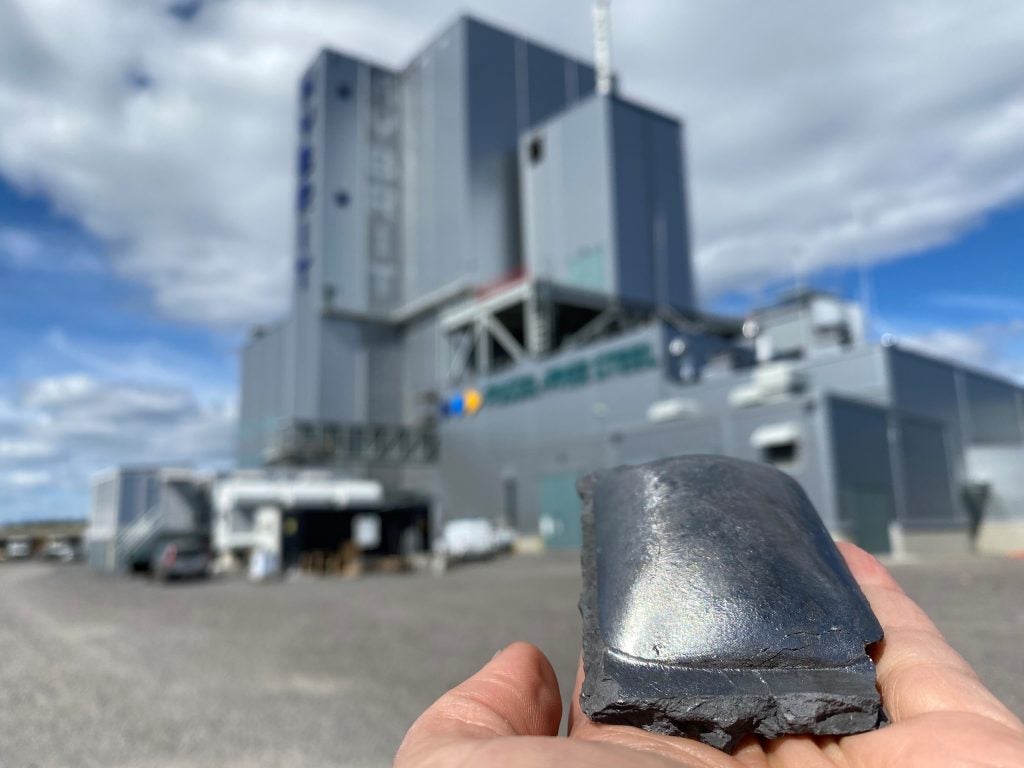

In June, the three companies demonstrated for the first time the pioneering process by producing about 100 metric tons of hydrogen-reduced sponge iron made at Hybrit’s pilot plant in Luleå.

With the new hydrogen-reduction process, Hybrit said in an article published in the journal Metals, the fossil CO2 emission decreases from 1600 kg/ton of crude steel to 25 kg/ton.

“In this example, in northern Sweden, the availability of renewable electricity, such as hydropower and wind power, together with good access to biomass used in the HYBRIT route replaces the fossil fuel used in the Blast Furnace route, thus eliminating most of the fossil CO2 emissions,” it noted in the article.

This first sponge iron has since been used to produce the first steel made with this breakthrough technology.

Simulations also showed that the price for electricity needed for the process can be lowered by 6–7 per cent by utilising fossil-free energy sources such as wind power and optimising the production time in the electrolysis and the size of the hydrogen storage.

“It’s a crucial milestone and an important step towards creating a completely fossil-free value chain from mine to finished steel,” Jan Moström, President and CEO of LKAB, said in a statement.

“By industrialising this technology in the future and making the transition to the production of sponge iron on an industrial scale, we will enable the steel industry to make the transition. This is the greatest thing we can do together for the climate,” Mr Mostrom added.

Hybrit says the goal is to deliver fossil-free steel to the market and demonstrate the technology on an industrial scale as early as 2026.

Using HYBRIT technology, SSAB says it can reduce Sweden’s total carbon dioxide emissions by approximately ten per cent and Finland’s by approximately seven per cent.

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies

Comments