This tiny section of the US Southeast could hold enough lithium to cover battery needs for years

Demand for lithium is rising as the world transitions toward clean energy and ramps up electric vehicle production

Your support helps us to tell the story

From reproductive rights to climate change to Big Tech, The Independent is on the ground when the story is developing. Whether it's investigating the financials of Elon Musk's pro-Trump PAC or producing our latest documentary, 'The A Word', which shines a light on the American women fighting for reproductive rights, we know how important it is to parse out the facts from the messaging.

At such a critical moment in US history, we need reporters on the ground. Your donation allows us to keep sending journalists to speak to both sides of the story.

The Independent is trusted by Americans across the entire political spectrum. And unlike many other quality news outlets, we choose not to lock Americans out of our reporting and analysis with paywalls. We believe quality journalism should be available to everyone, paid for by those who can afford it.

Your support makes all the difference.A source of lithium found in Arkansas could potentially meet the projected world demand for lithium in car batteries nine times over.

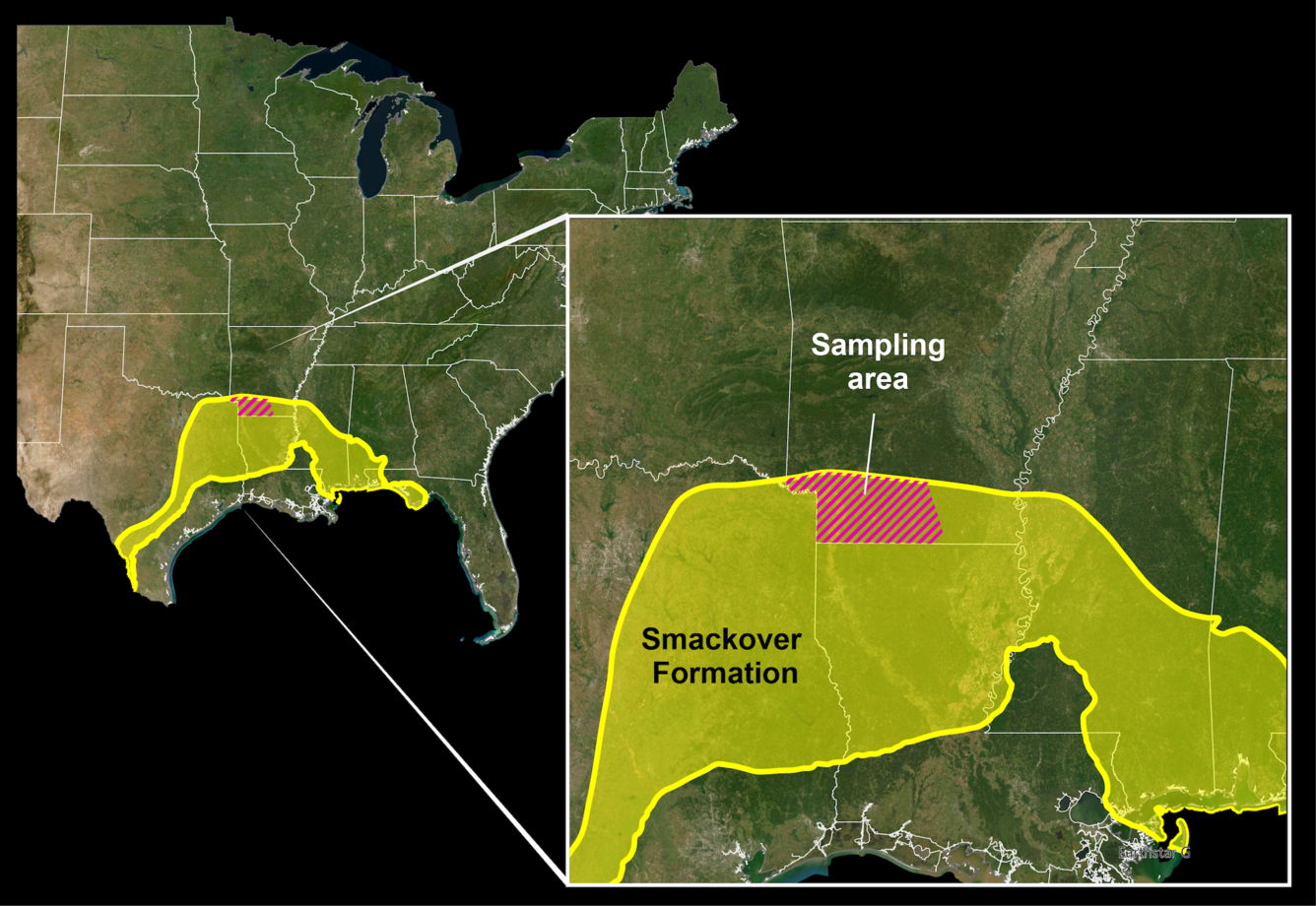

Between 5 and 19 million tons of lithium, a silvery-white metal that is used to power cell phones, laptops, and electric vehicles, are located between the southwestern portion of the state, at a site known as the Smackover Formation. The formation extends from Texas to Florida and is the relic of an ancient sea. It dates back between 145 to 200 million years ago, during the Jurassic period.

With the global demand for the critical mineral rising amid a transition toward clean energy, the U.S. Geological Survey, which conducted the research, said extracting the lithium would be a valuable opportunity.

“Lithium is a critical mineral for the energy transition, and the potential for increased U.S. production to replace imports has implications for employment, manufacturing and supply-chain resilience,” USGS Director David Applegate said in a statement.

To determine how much lithium is present in underground brine deposits, salty liquid found underground or on its surface, the agency used a combination of water testing and machine learning, a type of artificial intelligence. Samples from Arkansas were analyzed at a lab and compared with data from historic samples within a USGS database. Then, a machine learning model was used to combine the concentration of lithium in brines with geological data and create maps that predicted the region’s total lithium concentrations.

“We estimate there is enough dissolved lithium present in that region to replace U.S. imports of lithium and more,” said hydrologist Katherine Knierim, the study’s principal researcher. “It is important to caution that these estimates are an in-place assessment. We have not estimated what is technically recoverable based on newer methods to extract lithium from brines.”

Demand for lithium is expected to continue to grow and, right now, the US relies on imports for more than 25 percent of its lithium.

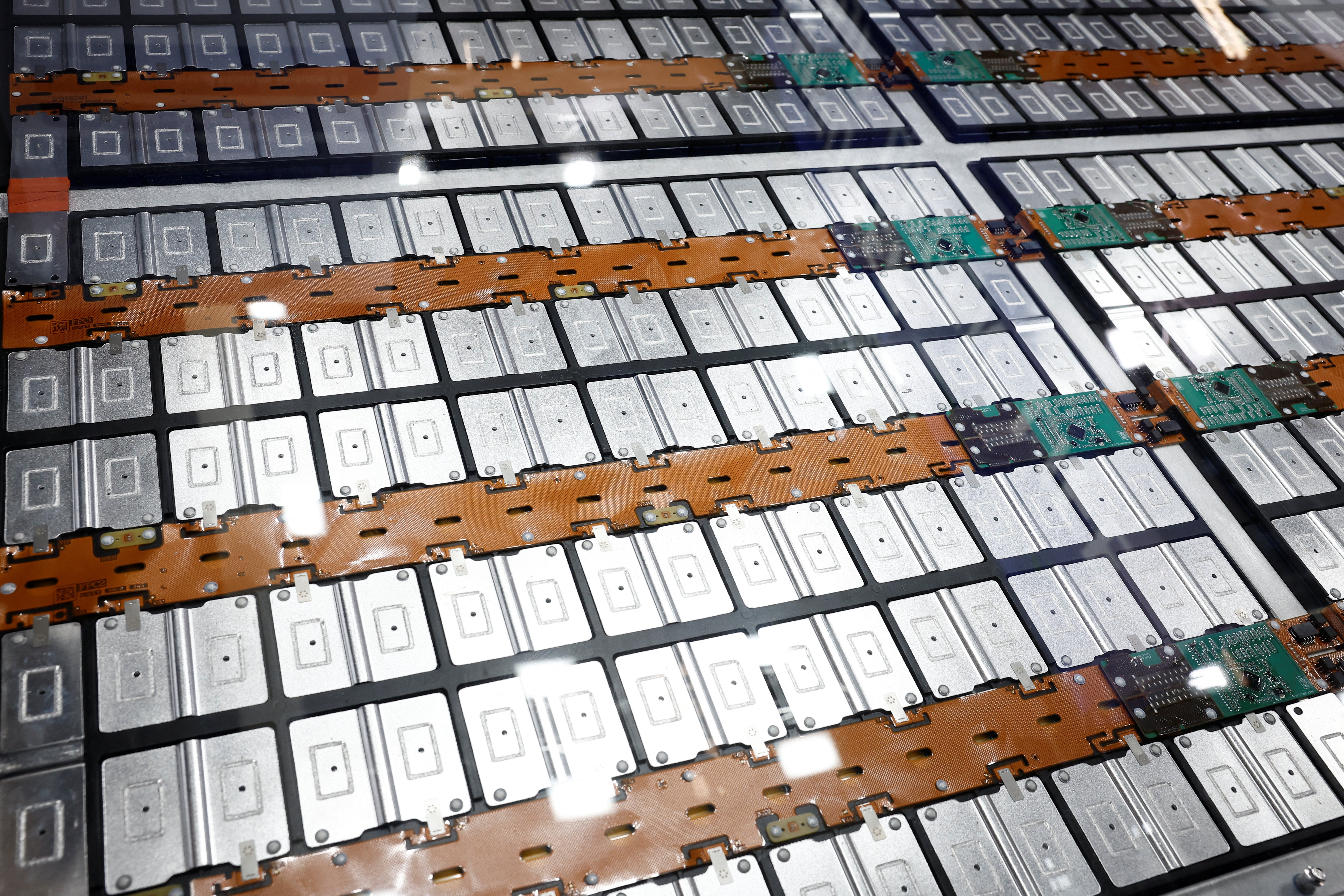

The International Energy Association said this year that electric vehicle battery demand will increase, with growth in electric vehicle sales pushing up demand. The group said electric vehicle battery deployment increased by 40 percent last year, with 14 million new electric cars. The current global value of battery packs in electric vehicles and energy storage applications is $120 billion. Even with current policy, the battery market is forecast to expand to a total value of $330 billion by 2030.

Energy and mining companies have long produced oil, gas and other natural resources in the formation and the industry has been working to produce raw materials needed for batteries in the US.

To extract lithium from brines, the liquid is pumped and then placed into pools. There, the water can evaporate, leaving behind the lithium. This, MIT notes, requires significant water use. Brine loss through mining can impact ecosystems and communities. Although, it is much less energy intensive than traditional hard rock mining. New methods of extraction are currently being tested.

Technology developed by researchers at Stanford University can sustainably extract lithium from brines at a price that is 40 percent less than today’s extraction method. The dominant technology costs about $9,100 per ton, the university said in August.

Join our commenting forum

Join thought-provoking conversations, follow other Independent readers and see their replies

Comments